-

Straße Name, NY 38954

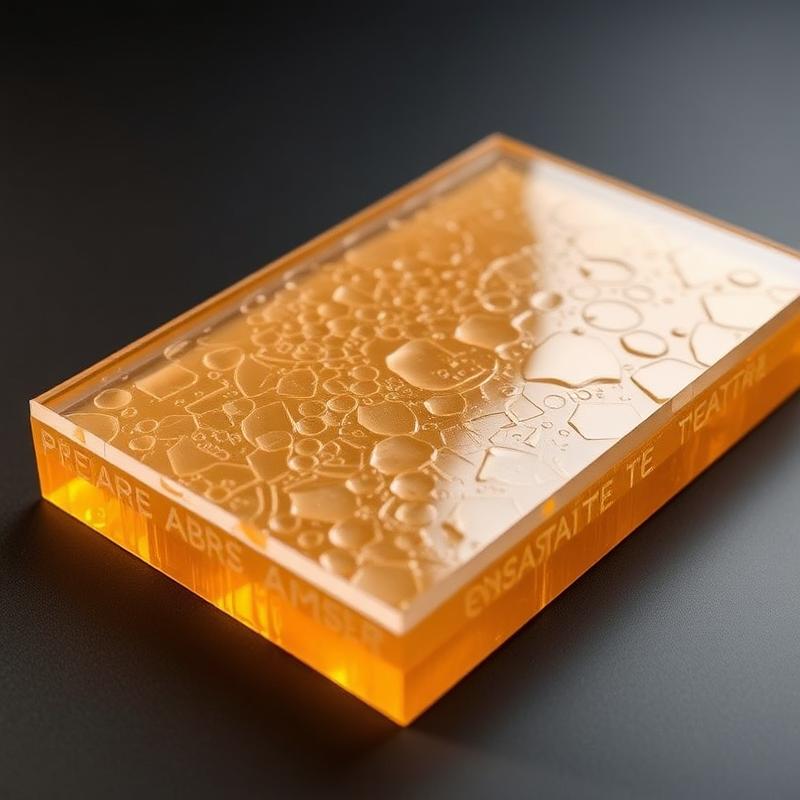

Acrylglasplatte mattiert

🕢 [ Füllen Sie das Formular aus und wir werden innerhalb von 30 Minuten antworten!]

Cut-to-Size Frosted Acrylic Sheets: The Perfect Solution for Privacy and Style

As a leading acrylic sheet factory and manufacturer, we specialize in providing high-quality, frosted acrylic sheets perfect for supermarkets, wholesalers, and building material markets. Our frosted plexiglass offers an elegant, opaque finish that provides privacy without sacrificing light transmission. We offer bulk ordering and cut-to-size options to meet the specific needs of your business, eliminating waste and streamlining your projects. Partner with us for reliable supply, competitive pricing, and exceptional customer service.

The Versatility of Frosted Acrylic Sheet

Frosted acrylic is an incredibly versatile material prized for its unique combination of freedom and light diffusion. The frosted finish, achieved through a specialized manufacturing process, scatters light evenly, creating a soft, elegant glow. This makes it an excellent choice for a wide range of applications. Unlike standard glass, acrylic is significantly more impact-resistant (8-23 times), reducing the risk of breakage during handling and installation. This is especially important in high-traffic areas like supermarkets and building material markets. The Acrylglasplatte mattiert also provides a degree of opacity, making it perfect for applications where privacy is desired, such as partitions, door inserts, and display cases. We can supply varying levels of frosted finish to accommodate your specific privacy requirements.

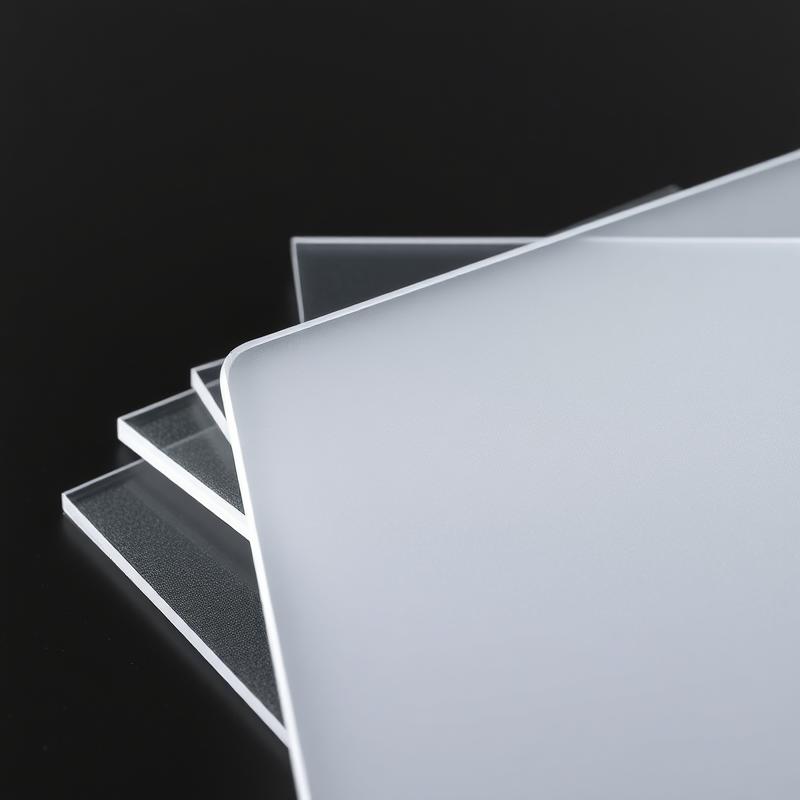

Our frosted acrylic are easily fabricated without significant loss of frosted appearance. They can be cut, drilled, and shaped to meet your precise specifications. The material is also lightweight, making it easy to handle and install. The available thickness can vary based on your needs, and we provide a wide range of sheet sizes to minimize waste and optimize your budget. The material can be used in various applications, including DIY projects, signage, lighting fixtures, and furniture.

Frosted Acrylic Sheet Thickness, Dimensions and Tolerances

The dimensions of our standard full sheets, as well as the sheet’s thickness tolerance, are as follows:

| Thickness (inch) | Thickness Tolerance | Sheet Size (inches) |

|---|---|---|

| 1/8 | +/- 0.01 | 48 x 96 |

| 3/16 | +/- 0.015 | 48 x 96 |

| 1/4 | +/- 0.02 | 48 x 96 |

| 3/8 | +/- 0.03 | 48 x 96 |

| 1/2 | +/- 0.04 | 48 x 96 |

| 3/4 | +/- 0.06 | 48 x 96 |

| 1 | +/- 0.08 | 48 x 96 |

Note: Custom sizes and thicknesses are available upon request. We provide cut-to-size service to meet your exact project requirements. Please contact us for a quote.

Superior Privacy and Light Diffusion with Frosted Plexiglass

Frosted plexiglass, also known as frosted acrylic, offers exceptional light diffusion properties, making it an ideal choice for applications where both illumination and privacy are needed. The frosted surface scatters light, reducing glare and creating a soft, even glow. This is particularly beneficial in settings such as supermarket display cases, where you want to showcase products attractively without harsh reflections. The strukturierte Acrylplatte surface also prevents a clear view of objects behind the sheet, providing the desired level of privacy. It serves as an excellent alternative to traditional glass in applications such as office partitions, shower doors, and furniture.

The level of light transmission and diffusion can be adjusted by selecting different thicknesses and finishes of our frosted plexiglass sheets. We provide various grades of frosting, from lightly frosted for a subtle effect to more opaque options for maximum privacy. Our team can help you select the perfect product to achieve the desired balance between light transmission and obscurity for your specific application. We can supply large quantity orders for wholesalers and building material markets. We provide consistent supply, competitive price and on-time shipping.

Enhanced Durability and Safety of Acrylic Sheet

Acrylic sheet, whether frosted or clear, boasts superior durability compared to traditional glass. Its impact resistance makes it far less prone to shattering, a critical safety advantage in high-traffic environments like supermarkets and retail spaces. This inherent strength also makes it a more reliable choice for applications such as signage, displays, and protective barriers. While we primarily cater to bulk orders, understanding the end-use scenarios helps us emphasize the product’s benefits to our target customers.

Furthermore, acrylic is significantly lighter than glass, making it easier and safer to handle and install, especially for larger projects. This reduced weight also translates to lower shipping costs, a significant benefit for wholesalers and building material markets managing large inventories. Even with its enhanced durability, acrylic is easy to cut and shape, allowing for customized solutions for diverse projects. Edge finishing options are available to provide a polished and professional look.

Environmental Impact and Usage Instructions

Acrylic is a recyclable material, and we are committed to sustainable manufacturing practices. We strive to minimize waste throughout the production process, and we encourage our customers to recycle their acrylic scraps. Specific recycling instructions may vary based on local regulations, so we advise checking with your local recycling facilities for detail.

“Acrylic sheet can be cut with a fine-tooth saw, such as a circular saw or jigsaw. Holes can be drilled using standard drill bits designed for plastic. Always use appropriate safety gear when working with acrylic.”

For optimal results when painting acrylic, use paints specifically formulated for plastic surfaces. Proper surface preparation is crucial for paint adhesion. Cleaning the acrylic sheet with a mild detergent and water before painting is recommended.

Contact us today for a free quote!

As a factory specializing in acrylic sheet manufacturing, we are your direct source for top-quality Acrylglasscheibe and farbige Acrylglasplatten, including frosted acrylic options. We provide competitive pricing, fast turnaround times, and custom fabrication services to meet your exact specifications. Whether you need pre-cut sheets or custom shapes with drilled holes, we have the capabilities to fulfill your order efficiently. We are committed to providing excellent customer service and support throughout the entire ordering process, from placing your order to shipping and delivery. Need help selecting the right product? Our experienced team is here to assist you.

Contact us to get price and details of shipping.

Advantages of Our Frosted Acrylic Sheets

Experience unmatched privacy and style! Our frosted acrylic offers superior durability, exceptional light diffusion, and easy customization, perfect for wholesalers and building material markets. Get bulk pricing and reliable, on-time delivery!

10 Dinge, die Sie beim Kauf von Produkten aus China beachten sollten

Hilfe-Center

Haben Sie eine Frage? Bitte prüfen Sie diese Frage und Antworten

Ja, wir verwenden 100% Premium-Acrylglas (PMMA) ohne recycelte Bestandteile, das für alle Produkte eine hervorragende Klarheit, UV-Beständigkeit und langfristige Haltbarkeit gewährleistet.

Wir sind für unser Qualitätsmanagement nach ISO 9001 zertifiziert und erfüllen die Umweltstandards REACH/SGS. Kundenspezifische Zertifizierungen (z. B. FDA für lebensmittelechtes Acryl) können auf Anfrage erteilt werden.

Standardartikel: 7-10 Tage. Sonderanfertigungen: 12-18 Tage je nach Komplexität. Eilaufträge können besprochen werden.

Ja. Wir bieten CNC-Schneiden, Lasergravieren, Thermoformen und Kantenpolieren. Senden Sie uns CAD-Dateien/DXF-Entwürfe für ein sofortiges Angebot. Mindestbestellmenge: 10 Stück pro Entwurf.

Standarddicke: 1mm-15mm. Farben: Klar, matt, 16+ transparente Farben und kundenspezifische Pantone-Farben (MOQ 500kg). Toleranz: ±0,2 mm.

Wir stellen 3 kostenlose Muster im Format A4 zur Verfügung. Der Kunde trägt die DHL/UPS-Versandkosten. Vorlaufzeit für Muster: 72 Stunden.

Farbabweichungen bei Acrylglasplatten können aufgrund verschiedener Faktoren auftreten, z. B:

Unterschiede zwischen den Produktionschargen: Leichte Änderungen der Pigmentkonzentration oder der Rohstoffe zwischen den Chargen.

Herstellungsbedingungen: Schwankungen der Temperatur, des Drucks oder der Aushärtezeit während der Produktion.

UV-Belastung: Längeres Sonnenlicht kann zum Verblassen oder zu Farbveränderungen führen.

Schneiden/Bearbeiten: Die beim Schneiden oder Bearbeiten entstehende Wärme kann die Oberflächenfarbe vorübergehend verändern.

An einem kühlen, trockenen, UV-geschützten Ort und vor direkter Sonneneinstrahlung geschützt lagern.

Lassen Sie die Schutzfolien bis zum Einbau intakt, um Kratzer oder chemische Reaktionen zu vermeiden.

Vermeiden Sie es, die Blätter mit ungleichmäßigem Druck zu stapeln, da dies zu spannungsbedingten Verfärbungen führen kann.

Kundenspezifische Farben verringern zwar die Risiken, aber absolute Konsistenz ist eine Herausforderung. Fordern Sie immer ein Vorproduktionsmuster an und vereinbaren Sie mit dem Lieferanten einen Toleranzbereich.